Wastewater

Wastewater

Our collection system consists of sewer mains, lift stations, and manholes.

Our permitted EPA and SD DANR treatment process includeds: Physical Treament, Biological Treatment, and Biosolids Treatment.

Consumer awareness can help keep the system running smoothly and rate increases reasonable. We appreciate you considering the value of the service that is provided to you. We all want to flush our toilets, feel confident that things will work as they should, and know that our environment is protected. One important way for us to work together is by only flushing items that can safely be flushed.

DO NOT FLUSH – Food – Flushable Wipes – Feminine Products – Grease

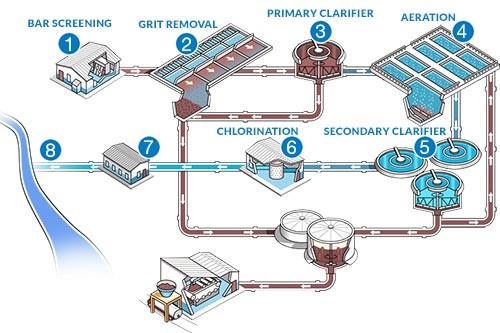

Eight Stages of Wastewater Process

Stage One — Bar Screening (Screen and Cutter combination)

Removal of large items from the influent to prevent damage to the facility’s pumps, valves and other equipment.

Stage Two — Screening (grit chambers)

Removal of grit by flowing the influent over/through a grit chamber.

Stage Three — Primary Clarifier

Initial separation of solid organic matter from wastewater.

Stage Four — Aeration

Air is pumped into the aeration basin to encourage conversion of NH3 to NO3 and provide oxygen for bacteria to continue to propagate and grow.

Stage Five — Secondary Clarifier

Treated wastewater flows into a secondary clarifier to allow any remaining organic sediment to settle out of treated water flow.

Stage Six — Chlorination (Disinfection) (May-September)

Chlorine is added to kill any remaining bacteria in the contact chamber.

Stage Seven — Water Analysis & Testing

Testing for proper pH level, ammonia, nitrates, dissolved oxygen, and residual chlorine levels to conform to the plant’s NPDES permit are critical to the plant’s performance. Also quarterly toxicity testing.

Stage Eight — Effluent Disposal

After meeting all permit specifications, clean water is reintroduced into the environment.